Vacuum-Insulated

Stainless Container

What is Vacuum-insulated

stainless container

A vacuum-insulated stainless steel container has a vacuum space between the double-layer structure to to keep the inside of the container warm or cold.

This structure effectively suppresses heat conduction and convection, achieving a high thermal insulation performance. Vacuum-insulated containers are utilized in a variety of applications requiring heat and cold retention.

Mechanism of vacuum-insulated container

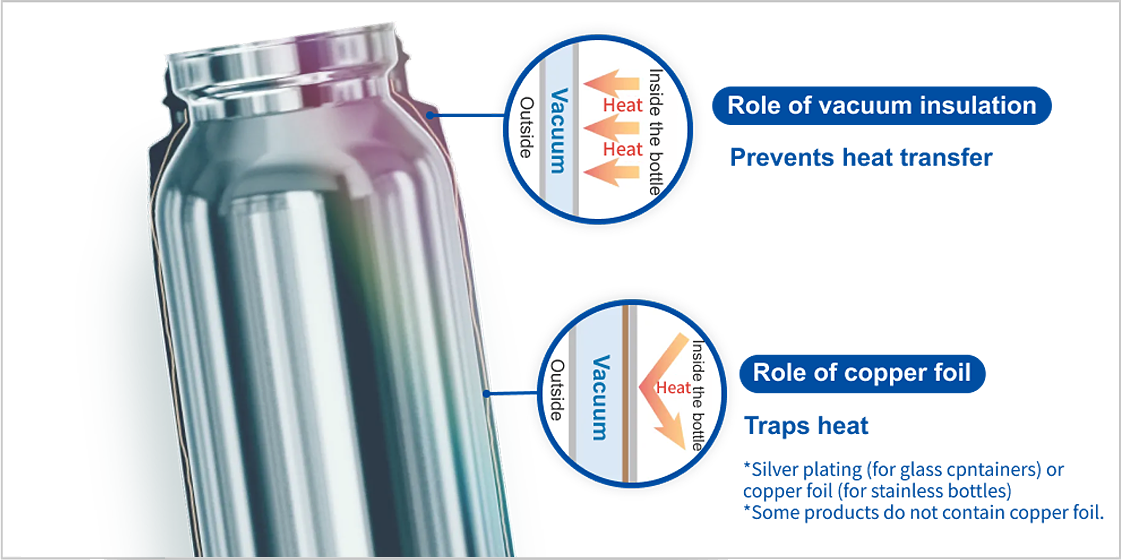

The vacuum layer between the inner and outer cylinders ensures conduction of heat or as little as possible.

In addition, the mirror finish on the inner surface of the container and the metal foil in the vacuum layer reflect radiant heat, thereby retaining heat energy inside.

These technologies enable vacuum insulated containers to maintain internal temperatures for extended periods of time.

Related Links

Key Features

High thermal insulation

The vacuum space between the inner and outer cylinders, the mirror finish on the inner surface, and the metal foil in the vacuum space suppress the three properties of heat; “conduction, convection, and radiation” and maintain the temperature inside the vacuum-insulated container for a long time.

Lightweight and

compact

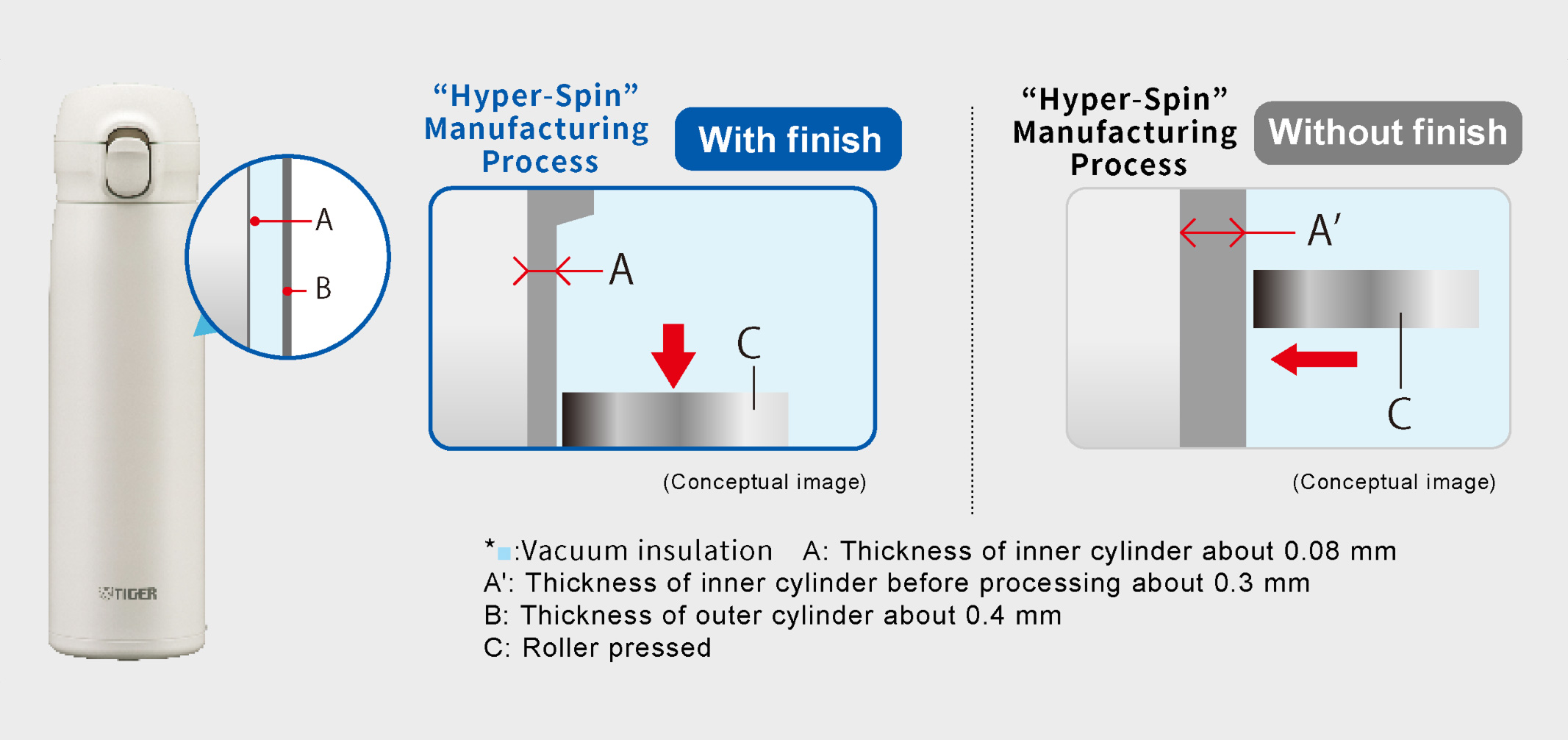

The material of the inner cylinder is made as thin as possible using Tiger’s unique spinning process, realizing surprising lightness.

Durability

The use of durable stainless steel ensures robustness to withstand long periods of use.

High insulation performance

The heat- and cold-retention technology developed from the development of glass vacuum flasks has evolved into advanced vacuum insulation technology. High thermal insulation performance.

This technology has been utilized in a variety of cutting-edge industrial fields, including the space industry, as well as stainless steel vacuum flasks.

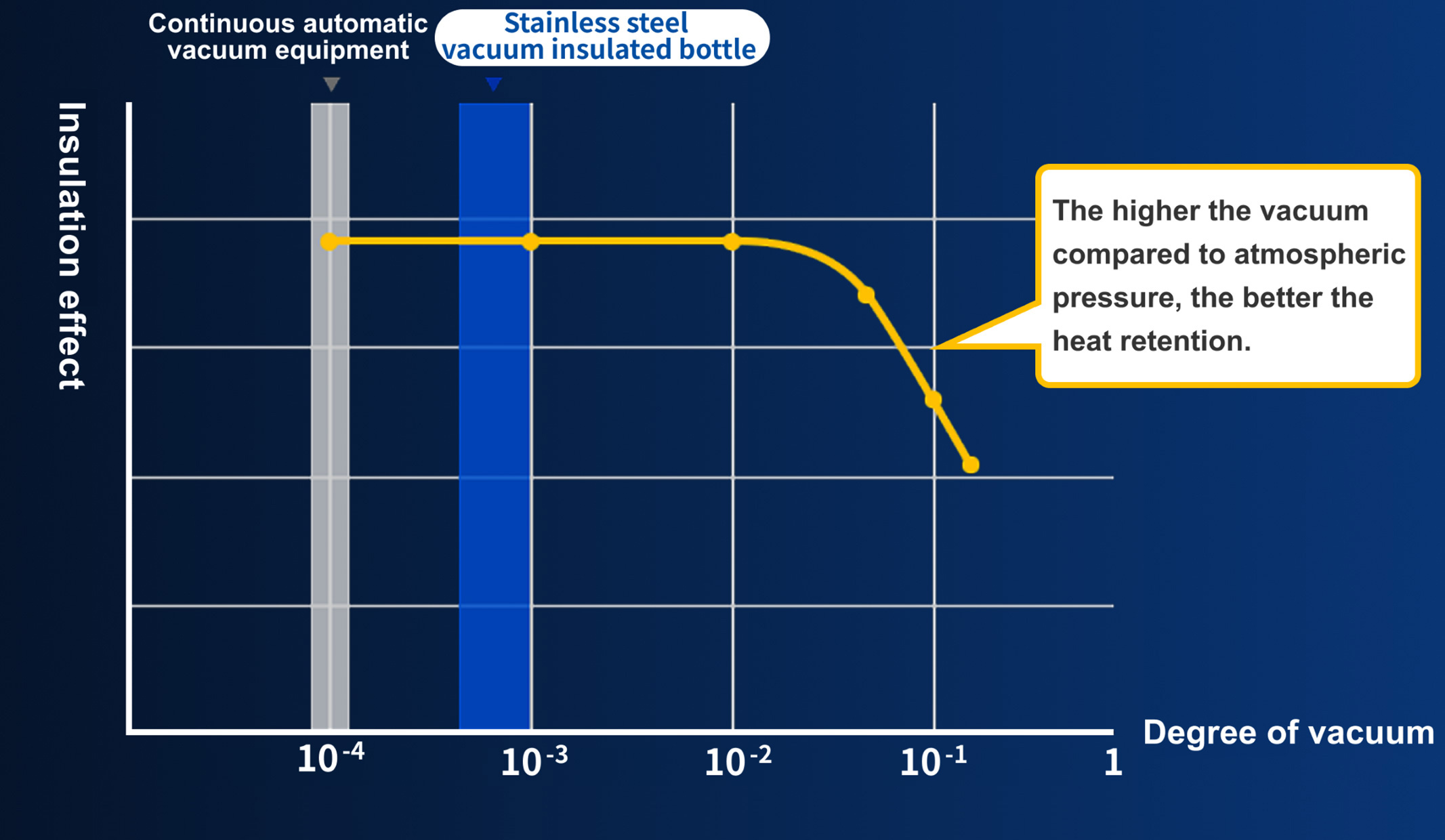

High vacuum properties

Fully sealed by continuous automatic vacuum equipment to a near space vacuum.

Numerous containers are placed in a high-vacuum furnace (continuous vacuum equipment) at 10-4 Pa and 500℃ and the brazing filler is melted in the furnace to fully seal the exhaust vent while the vacuum furnace is being evacuated.

The vacuum brazing method realizes a high vacuum (10-³Pa) equivalent to an altitude of approximately 90 to 250 km above the ground, which is the borderline between space and outer space.

Surprisingly light and compact

The material of the inner cylinder is made as thin as possible using Tiger’s unique spinning process, realizing surprising lightness.

- *This is an example of Vacuum-Insulated Bottle MKR-W Series

Benefits of vacuum-insulated

stainless containers

Benefit

01

Reduction in energy costs

Vacuum insulation technology provides excellent thermal insulation performance. This increases heat and cold insulation and improves energy efficiency. It significantly reduces energy consumption and contributes to cost reduction.

Benefit

02

Improved accuracy of temperature control

Because it minimizes temperature changes, it is also suitable for use in fields where precise temperature control is required. This improves product quality and performance.

Benefit

03

Reduction in transport costs

Lightweight and compact, it is also easy to transport, helping to reduce transport costs.

Benefit

04

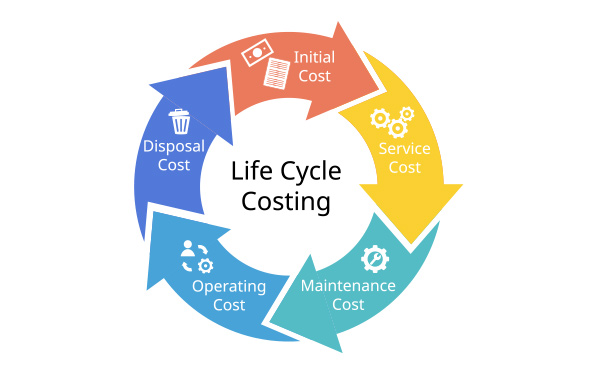

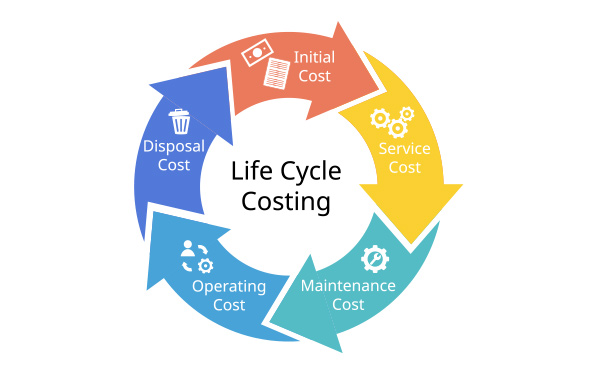

Reduction in life cycle costs

Durable stainless steel material is used, which does not deteriorate easily even after long-term use, reducing the frequency of replacement and the total cost (life cycle cost).

Benefit

05

Recyclable

Tiger Corporation started setting up collection boxes to collect used stainless-steel bottles for personal use in October 2021.

We work on recycling stainless-steel bottles.

For details, go to https://www.tiger-corporation.com/ja/jpn/feature/sdgs/

- *The collection boxes above handle vacuum-insulated bottles, but stainless steel vacuum-insulated containers can also be recycled.

Fields of application for

vacuum-insulated stainless containers

Vacuum-insulated stainless containers are used in many industries due to their excellent insulation performance and reliability.

They are used not only for the storage of foods and beverages, but also for medical, industrial and space applications.

Medical field

Industrial field

Environmental energy field

Space field

Transport field

Case Studies

Other solutions

About Industrial Equipment Solutions

Contact Us

For more information, contact us from here;

On research and development, methods of applying vacuum insulation technology,

and inquiries about partnership