Our Strengths

For over a century, Tiger has collaborated with numerous industries, leveraging its expertise in hot and cold insulation technology to drive innovation.

Our extensive experience and cutting-edge solutions empower us to provide robust support to your business.

Three strengths

01

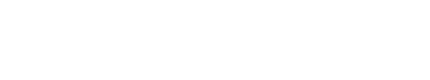

Unique technology to utilize and

manipulate heat effectively

Vacuum insulation technology and heat control technology

Tiger has evolved its heat and cold insulation technology over 100 years. This technology has been well received in products for commercial use and OEM manufacturing.

Our technology is used in various business settings such as in the field of food and beverages, medical equipment and industrial applications where temperature control is critical. We can also customize our solutions to meet the needs of our partners.

02

Design, development, and quality control capabilities

that meet the high standards of commercial use

Providing products that meet strict quality standards

In addition to design, development, and quality control for daily necessities such as stainless steel bottles, we also have a design, development, and quality control system in place for industrial equipment such as automobiles and space-related products that require standards beyond those of daily necessities.

This is one of the reasons why we are trusted by many of our partner companies.

03

Flexible customization and

solution offerings

Realize optimal proposals for partner companies

We do not just provide products, but also offer flexible customization to meet your business needs.

A dedicated team will propose optimal solutions to solve your problems and build partnerships to create new value together.