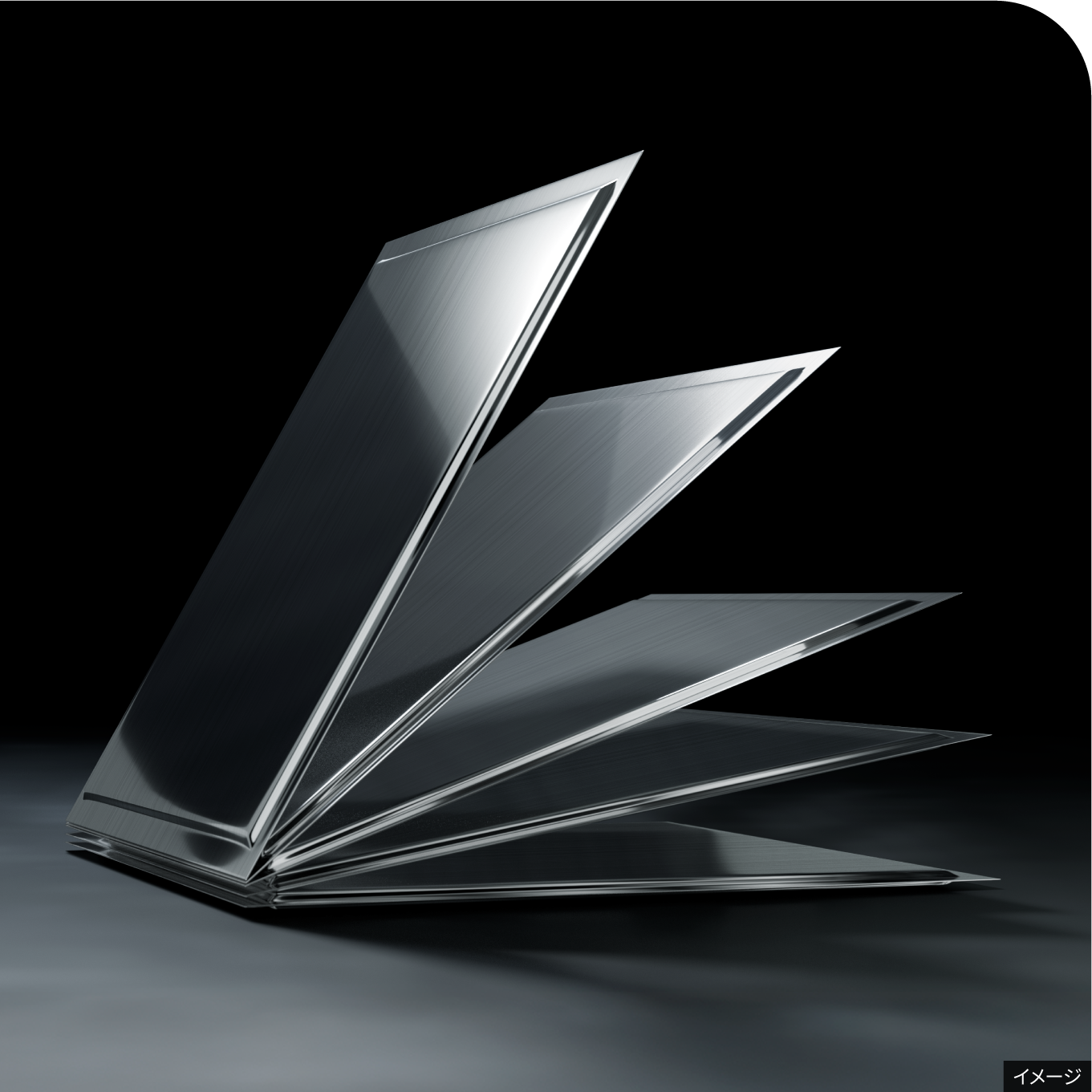

TIVIP

Stainless Steel

Vacuum Insulation Panel

What is Stainless Steel

Vacuum Insulation Panel?

TIVIP

A stainless Steel Vacuum Insulation Panel (TIVIP: TIGER Vacuum Insulated Panel) is a high-performance insulating material that uses stainless steel foil to create a vacuum inside the panel, resulting in very low heat conduction.

Compared with conventional insulation materials, it provides high thermal insulation effect even with very thin layers. These properties have attracted attention in various fields where energy conservation and efficient use of space are important.

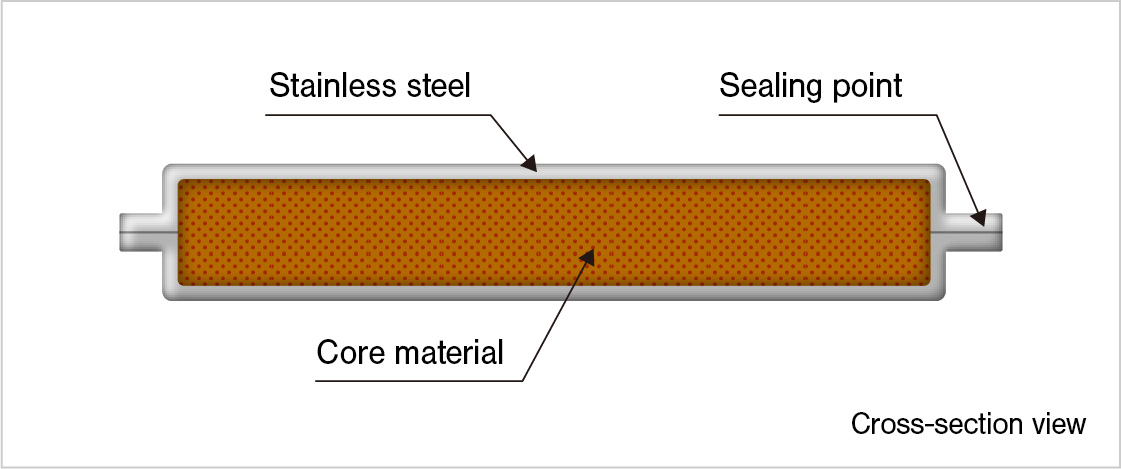

Mechanism of Stainless Steel Vacuum Insulation Panel

This material is made by creating a vacuum inside a double-layered stainless steel foil to enhance thermal insulation performance. In addition, a core material is placed inside to seal it in order to maintain its shape.

Related Links

Key Features

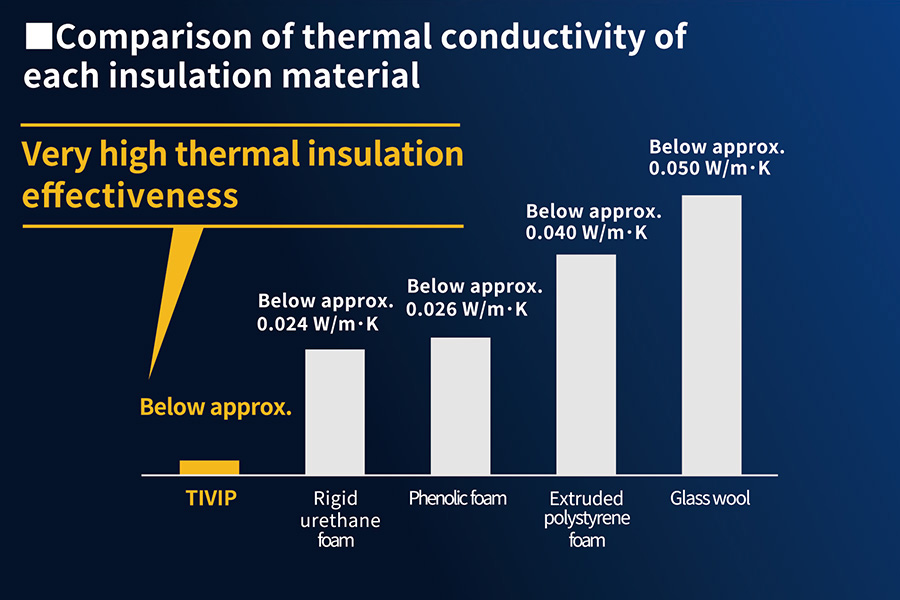

High thermal insulation

We apply vacuum insulation technology used in vacuum-insulated bottles. It has a very high thermal insulation effect compared with conventional insulation materials.

Long service life

Using the same material as vacuum-insulated bottles, stainless steel, and the sealing technology we have developed, the vacuum can be maintained for more than 30 years, giving it a long service life.

- *Estimated value based on actual gas permeability of the materials used (calculated by Tiger’s in-house measurement method)

Non-flammability

Unlike ordinary vacuum insulation materials, this material is made of stainless steel, making it nonflammable and highly safe.

- *Source: Ministry of Land, Infrastructure, Transport and Tourism’s “Study Policy in the Standard for Indication and Evaluation Methods (Energy Conservation)”

Realized with High thermal insulation, Long service life, and Nonflammability

Because the interior is a vacuum, the heat conductivity is less than 0.0025 W/m・K*1, which is approximately 10 to 25 times higher than that of conventional heat insulators.

Furthermore, by using stainless materials and applying the vacuum insulation technology for vacuum bottles to create a panel, we made it possible to maintain nonflammability and high thermal insulation properties over a long period of time, something that was not possible with conventional vacuum insulation materials.

This has enabled us to maintain vacuum insulation for a long period of time (more than 30 years)*2, thereby achieving safety through its long service life and nonflammability.

- *1 Initial measured values based on JIS A 1412-2 for a prototype 10 mm thick and 440 mm square or larger in size (calculated by our measurement method)

- *2 Estimated value based on actual gas permeability of the materials used (calculated by Tiger’s in-house measurement method)

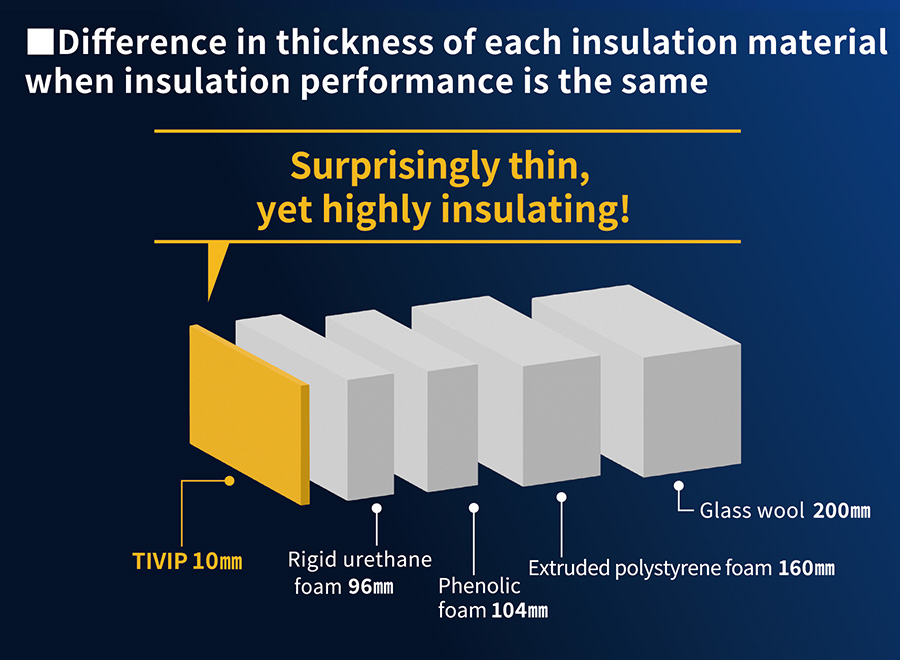

- *This is an illustration of thickness calculated based on thermal conductivity quoted from the Ministry of Land, Infrastructure, Transport and Tourism’s “Study Policy in the Standard for Labeling and Evaluation Methods (Energy Conservation)”. Actual thickness may vary depending on product and usage conditions.

Realized with Surprising Thinness

Equivalent heat insulation effect can be obtained with about 1/10th the thinness of urethane foam*3

- *Thermal resistance R=0.01/0.0025=4.00 m2K/W for a prototype of TIVIP with a thickness of 10 mm and size of over 440 mm square, Thermal resistance R=0.1/0.024=4.16 m2K/W for rigid polyurethane foam of a thickness of 100 mm and size of over 440 mm square

Watch a video of TIVIP

The person in charge of development of the stainless-steel-sealed vacuum insulation panel (TIVIP) introduces the product in a video.

Benefits of Stainless Steel

Vacuum Insulation Panel

Benefit

01

Reduction in energy costs

Utilizing stainless steel vacuum insulation panel for transport refrigeration containers and building materials can reduce the use of electric energy required to maintain temperature, thereby contributing to CO2 reduction and lower running costs.

Benefit

02

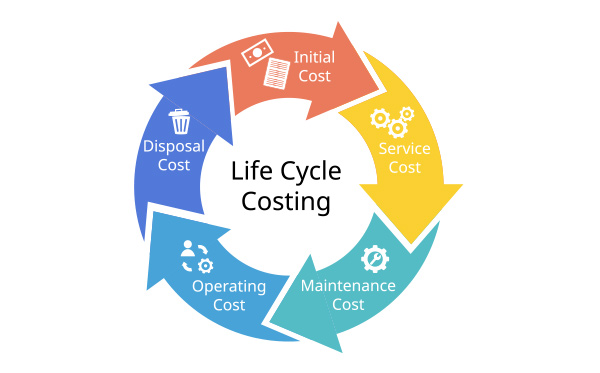

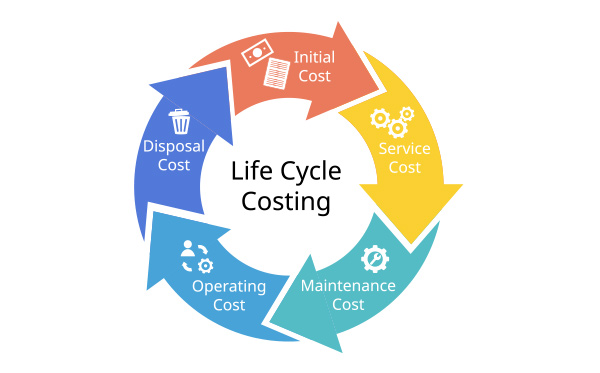

Reduction in life cycle costs

The vacuum can be maintained for more than 30 years and has a long life, significantly reduces the frequency of replacement of insulation materials and the total cost (life cycle cost) over the service life of the shipping container and building.

- *Estimated value based on actual gas permeability of the materials used (calculated by Tiger’s in-house measurement method)

Benefit

03

High safety

Highly nonflammable, it reduces the risk of fire, thus increasing the safety of the product and the building as a whole.

Benefit

04

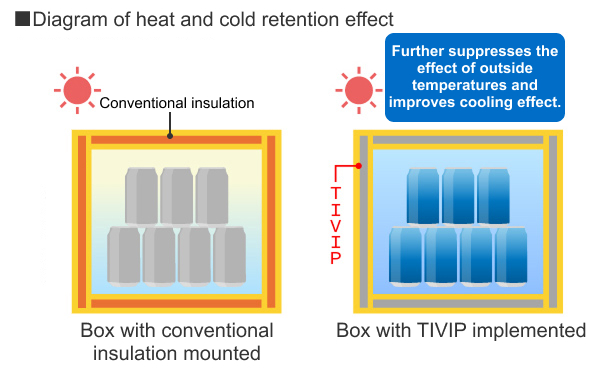

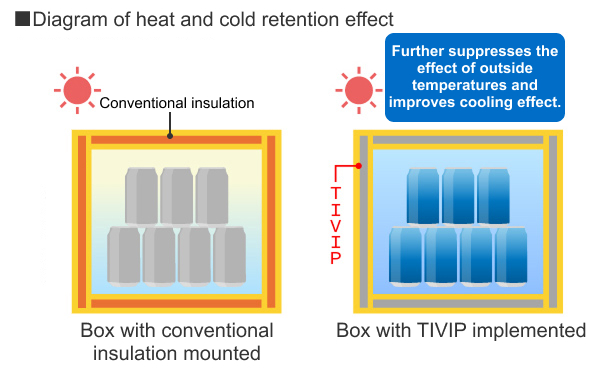

Improved cooling effect

Even with the same thickness as conventional insulation, higher insulation is possible, resulting in improved heat and cold retention.

Benefit

05

Recyclable

Tiger Corporation started setting up collection boxes to collect used stainless-steel bottles for personal use in October 2021.

We work on recycling stainless-steel bottles.

For details, go to https://www.tiger-corporation.com/ja/jpn/feature/sdgs/

- *The collection box above handles vacuum insulated bottles, but stainless steel vacuum insulation panel can also be recycled.

Fields of application for

Stainless Steel Vacuum Insulation Panel

Stainless steel sealed vacuum insulation panels are expected to be used in a variety of industrial fields due to their outstanding thermal insulation performance.

We will contribute to the technological innovation of the next generation, especially in the fields of transport and building materials, where energy efficiency and temperature control are required.

Transport field

Building materials field

Medical field

Industrial field

Environmental energy field