Highly insulating, long-lasting, and nonflammable vacuum insulation reduces CO₂ emissions required to maintain temperature during transportation

Highly insulating, long-lasting, and nonflammable vacuum insulation reduces CO₂ emissions required to maintain temperature during transportation

Reefer containers (frozen and refrigerated) and cold storage boxes using the newly developed “Stainless Steel Vacuum insulated reefer Insulation Panel”

will be used for the first time for cold storage transportation within the Osaka-Kansai Expo 2025.

Tiger Corporation (President: Yoshisato Kikuchi, Head Office: Kadoma, Osaka), a world leader in thermal control technology, in cooperation with Nippon Express and Gifu Plastic Industry, will use the newly developed Stainless Steel Vacuum Insulation Panel (TIVIP: TIGER Vacuum Insulated Panel) for the first time for cold transportation in and out of the Expo 2025 in Osaka, Japan (hereinafter referred to as “Expo 2025”), starting in May 2025.

The Stainless Steel Vacuum Insulation Panel (TIVIP) is a high-performance insulation material made of stainless steel that creates a vacuum inside the panel to keep heat conduction extremely low. It was newly developed by applying the vacuum insulation technology that we have been advancing for more than 100 years. The use of stainless steel has made it possible to maintain nonflammability and high thermal insulation properties over a long period of time, which was not possible with conventional nonstainless steel vacuum insulation materials.

Stainless Steel Vacuum Insulation Panel is an environmentally sustainable material that contributes to the reduction of CO₂ emissions by reducing the use of electric energy required to maintain temperature by utilizing it in cold storage containers for transportation and in building materials.

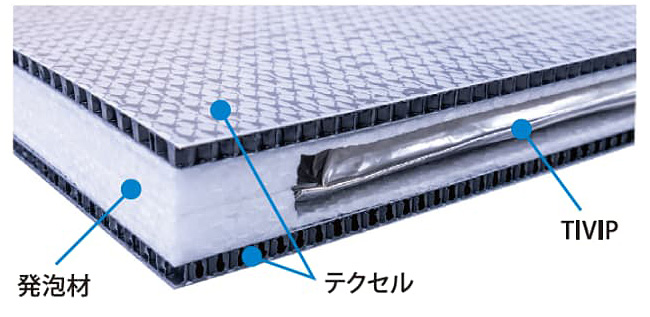

Stainless Steel Vacuum Insulation Panel *Images are for illustrative purposes only.

Vacuum insulated reefer container with Stainless Steel Vacuum Insulation Panel

In collaboration with Nippon Express and Gifu Plastic Industry, we will utilize (1) Vacuum insulated reefer containers, (2) Vacuum Insulated Protect BOXes, and (3) Vacuum Insulated Roll BOXes for cold transport (storage) inside and outside the Expo venue as the first full-scale demonstration test site.

In 2023, we will celebrate the 100th anniversary of our founding, and our “vacuum insulation technology,” which is our core business, has been evolving as we take on the challenge of entering the space field. We will contribute to the carbon neutrality of the world through our Stainless Steel Vacuum Insulation Panel, which combines our strength in “vacuum insulation technology” and our stainless steel processing technology that we have continued to refine.

Demonstration example at the Expo venue

(1) Vacuum insulated reefer container

Installed in a warehouse outside the venue/outdoors.

TIVIP Comparison of power consumption with and without additional implementation (energy saving visualization), Conducted carbon dioxide emissions comparison.

(2) Vacuum Insulated Protect BOX

for transportation within the venue from a warehouse outside the venue.

For transporting refrigerated cargo to pavilions/restaurants, etc. within the Expo venue.Utilize insulation protection box

(3) Vacuum Insulated Roll BOX

For delivery to each pavilion/restaurants from the in-venue receiving area.

Insulated carts are used to transport refrigerated cargo to pavilion/restaurants, etc. within the Expo venue. within the Expo site.

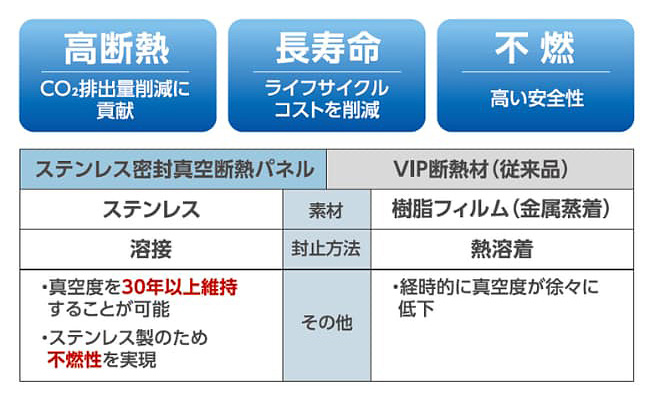

Features of Stainless Steel Vacuum Insulation Panel (TIVIP)

This is a high-performance heat insulator with very low thermal conductivity by creating a vacuum inside the panel.

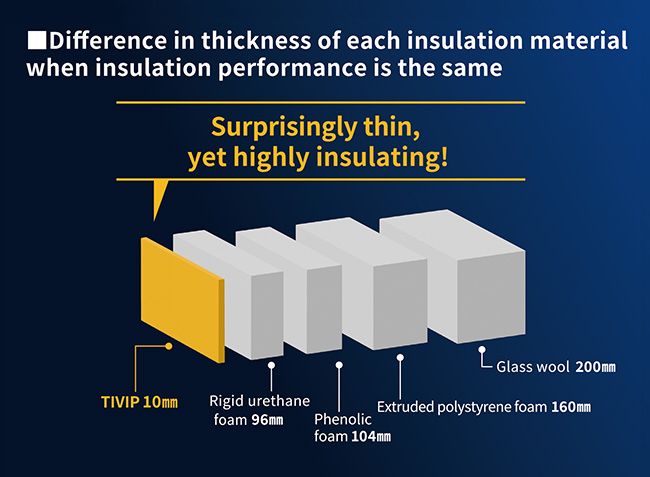

Compared to general insulation materials other than vacuum insulation, it exhibits high thermal insulation effectiveness even at very thin thicknesses. Due to these characteristics, it is expected to be used in fields where energy conservation and space efficiency are important. In addition, the use of stainless steel makes it possible to maintain nonflammability and high thermal insulation properties over a long period of time, which was not possible with conventional nonstainless steel vacuum insulation materials.

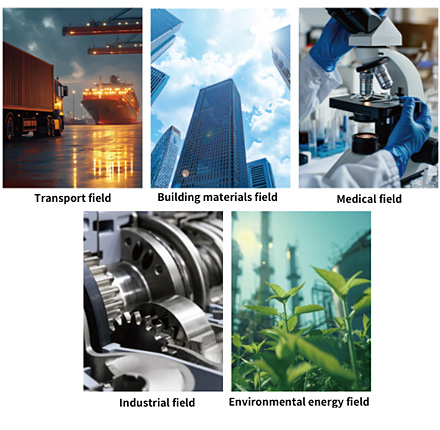

Fields of application for Stainless Steel Vacuum Insulation Panel

Stainless steel sealed vacuum insulation panels are expected to be used in a variety of industrial fields due to their outstanding thermal insulation performance. We will contribute to the technological innovation of the next generation, especially in the fields of transport and building materials, where energy efficiency and temperature control are required.

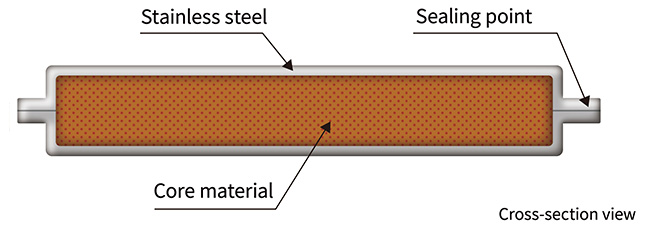

Mechanism of Stainless Steel Vacuum Insulation Panel

This material is made by creating a vacuum inside a double-layered stainless steel foil to enhance thermal insulation performance. In addition, a core material is placed inside to seal it in order to maintain its shape.

Realized with High thermal insulation, Long service life, and Nonflammability

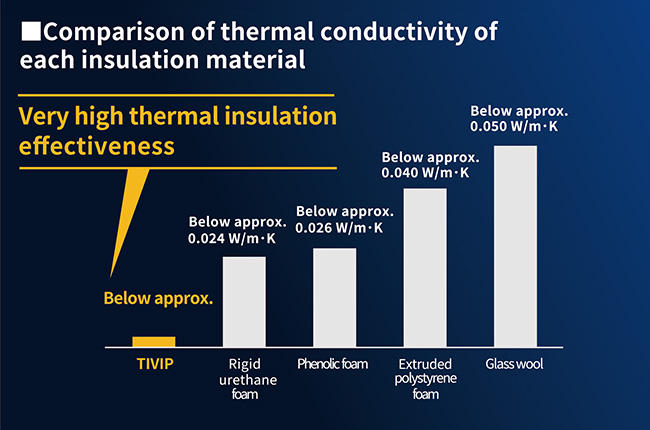

Because the interior is a vacuum, the heat conductivity is less than 0.0025 W/m/K*1, which is approximately 10 to 25 times higher than that of conventional heat insulators.

Furthermore, by using stainless materials and applying the vacuum insulation technology for vacuum bottles to create a panel, we made it possible to maintain nonflammability and high thermal insulation properties over a long period of time, something that was not possible with conventional vacuum insulation materials.

This has enabled us to maintain vacuum insulation for a long period of time (more than 30 years)*2, thereby achieving safety through its long service life and nonflammability.

*1 Initial measured values based on JIS A 1412-2 for a prototype 10 mm thick and 440 mm square or larger in size (calculated by our measurement method)

*2 Estimated value based on actual gas permeability of the materials used (calculated by Tiger’s in-house measurement method)

*Source: Ministry of Land, Infrastructure, Transport and Tourism’s “Study Policy in the Standard for Indication and Evaluation Methods (Energy Conservation)

Realized with Surprising Thinness

Equivalent heat insulation effect can be obtained with about 1/10th the thinness of urethane foam

*Thermal resistance R=0.01/0.0025=4.00 ㎡K/W for a prototype of TIVIP with a thickness of 10 mm and size of over 440 mm square,

Thermal resistance R=0.1/0.024=4.16 ㎡K/W for rigid polyurethane foam of a thickness of 100 mm and size of over 440 mm square

*This is an illustration of thickness calculated based on thermal conductivity quoted from the Ministry of Land, Infrastructure, Transport and Tourism’s “Study Policy in the Standard for Labeling and Evaluation Methods (Energy Conservation). Actual thickness may vary depending on product and usage conditions.

Collaborative Partners in the Demonstration Experiment at Expo

For use in the Osaka/Kansai Expo, we sandwich our newly developed Stainless Steel Vacuum Insulation Panel “TIVIP” with Gifu Plastic Industry‘s lightweight and high-strength material, TECCELL, a resin honeycomb panel, to protect TIVIP and create a lightweight and strong insulation unit panel.

By using these heat insulation unit panels in Nippon Express’ transportation packaging tools, such as the “Protect BOX”, high-performance cold storage transportation has become possible. Conventional frozen, refrigerated, and temperature-controlled transportation requires the use of cold and heat storage materials to maintain temperature, but these materials are no longer necessary, resulting in a significant reduction in electricity consumption.

Tiger Corporation collects and recycles stainless steel bottles that are no longer needed at home, regardless of manufacturer. The TECCELL used in this project is made of recycled PP resin from collected bottles.

As the core company of the NX Group, Nippon Express provides high-quality, sustainable logistics services globally, utilizing air, ocean, rail, truck, warehousing, and IT. It is also the “recommended logistics provider” and “designated on-site cargo handling provider” for the Osaka/Kansai Expo.

Manufactures and sells plastic industrial materials, industrial parts, and medical parts, as well as daily commodities and water pipe fittings. TECCELL, a next-generation honeycomb core material with extremely high specific strength and specific rigidity, is being commercialized.

To be exhibited at the”Future Society Showcase Project/Future Life Expo” and “Future Life Experience”

The “Stainless Steel Vacuum Insulation Panel Technology” is being developed and demonstrated with the support of the Osaka Prefectural Government’s “Carbon Neutral Technology Development and Demonstration Project,” a program that encourages companies to develop and demonstrate cutting-edge technologies that contribute to carbon neutrality.

Part of the “stainless-steel-sealed vacuum insulation panel technology” developed in this project will be exhibited at the “Future Society Showcase Project/Future Life Expo: Future Life Experience” of Expo 2025 Osaka, Kansai, Japan from October 7 to October 13, 2025.

Date and Time: Tuesday, October 7 to Monday, October 13, 2025

Venue: Inside Expo 2025 Osaka, Kansai, Japan site (West Gate side) Future Life Village, Future Life Experience

Exhibits: Tiger, Development and demonstration of long-lasting and nonflammable stainless-steel-sealed vacuum insulation panel technology

*The booth will be a joint booth of the Osaka Prefectural Government’s “Carbon Neutrality Technology Development and Demonstration Project” participant companies.

Caution: A separate Expo admission ticket is required for admission to “Future Life Experience.” To purchase a ticket, please visit the official website of the Japan Association for the 2025 World Exposition.

Sponsor: Japan Association for the 2025 World Exposition

Industrial Equipment Solutions Page for Corporate Customers Opens Today

Tiger Corporation’s official website has today launched a new page to provide industrial equipment solutions for corporate customers, including Stainless Steel Vacuum Insulation Panels.

Tiger Corporation Industrial Equipment Solutions Page

https://www.tiger-corporation.com/ja/jpn/for-business/

For inquiries from corporate customers, please contact

https://www.tiger-corporation.com/ja/jpn/support/inquiry/inquiry-industrial-equipment/

Click here to watch a video about Stainless Steel Vacuum Insulation Panel

https://youtu.be/U-65yP4W-Ds

About Tiger Corporation

Founded in 1923 with the production of “Tiger” glass vacuum flasks for the Japanese domestic market. Tiger has been pursuing temperature-related technologies for more than 100 years, aiming to realize its vision of “To spread joyous harmony throughout the world.” . We have been manufacturing and selling vacuum insulated bottles and other vacuum insulated containers (vacuum flasks) for home and business use, cooking appliances such as rice cookers, and industrial components and products for transportation, construction, space, medical care, and other fields in more than 60 countries around the world by applying our “vacuum insulation technology” and “heat control technology.